YYAudio RCA connector welding is a valuable skill for anyone looking to improve their audio setup. By learning how to solder these connectors properly, you can achieve better sound quality and create more reliable connections in your audio equipment. In this guide, we will walk you through the simple steps of welding YYAudio RCA connectors, helping you gain the confidence and skills to get professional results.

At first, welding RCA connectors may seem a bit challenging, but don’t worry! With the right tools and techniques, you’ll find it easier than you think. This article from Wiki247 will guide you through everything you need, from gathering your materials to troubleshooting any problems you might encounter. By the end, you’ll have all the knowledge you need to create strong, durable connections for all your audio projects.

Understanding YYAudio RCA Connectors: Basics and Benefits

YYAudio RCA connectors are popular in audio setups for connecting devices like speakers and amplifiers. They consist of two parts: an inner pin and an outer ring. The inner pin carries the audio signal, while the outer ring serves as a ground connection. This simple design helps ensure reliable sound quality. When you learn YYAudio Rca Connector how to weld, you create strong connections that enhance audio performance.

The benefits of using these connectors are significant. For one, they transmit audio without much interference. By using YYAudio RCA connectors, you can expect clear and crisp sound from your audio equipment. Understanding how to work with these connectors can lead to better overall performance in your audio system, especially when you know YYAudio Rca Connector how to weld properly.

Additionally, knowing how to weld these connectors is a valuable skill. Proper welding ensures strong connections, which can enhance the durability of your audio setup. If you’re looking to create custom cables or upgrade your audio equipment, mastering the process of YYAudio Rca Connector and how to weld is essential for achieving professional-grade results.

| Specification | Details |

| Connector Type | RCA (phono) connector |

| Material | Typically gold-plated for better conductivity |

| Wire Gauge | Usually 22 to 24 AWG for audio applications |

| Solder Type | Use rosin-core solder for better adhesion |

| Welding Method | Soldering with a soldering iron |

| Temperature | Recommended soldering iron temperature: 350°C (662°F) |

| Preparation | Strip insulation from wires (about 1/4 inch) |

| Joint Type | Use a butt joint for connecting wires to the RCA connector pins |

| Heat-Shrink Tubing | Optional for added insulation and protection |

| Testing | Use a multimeter to test continuity after welding |

Essential Tools for Welding YYAudio RCA Connectors

To successfully weld YYAudio RCA connectors, you will need some essential tools. First, a soldering iron is crucial. It should have a fine tip to allow for precise soldering. This tool is necessary for melting solder and making secure connections to the connectors. Understanding which tools to use when learning YYAudio Rca Connector and how to weld can make the process easier.

Next, you will need solder, which is a metal used to join the wires and connectors. It usually comes in a coil form and is made of materials like tin and lead. Using the right type of solder is important for electrical connections when you are focused on the YYAudio Rca Connector and how to weld effectively.

Additionally, wire strippers are necessary for preparing your cables. This tool helps you remove the outer insulation from the wires, exposing the inner wires for welding. Finally, a pair of pliers can help hold everything in place while you work. Having these tools ready will make the process of YYAudio Rca Connector’s ability to weld much easier and more efficient.

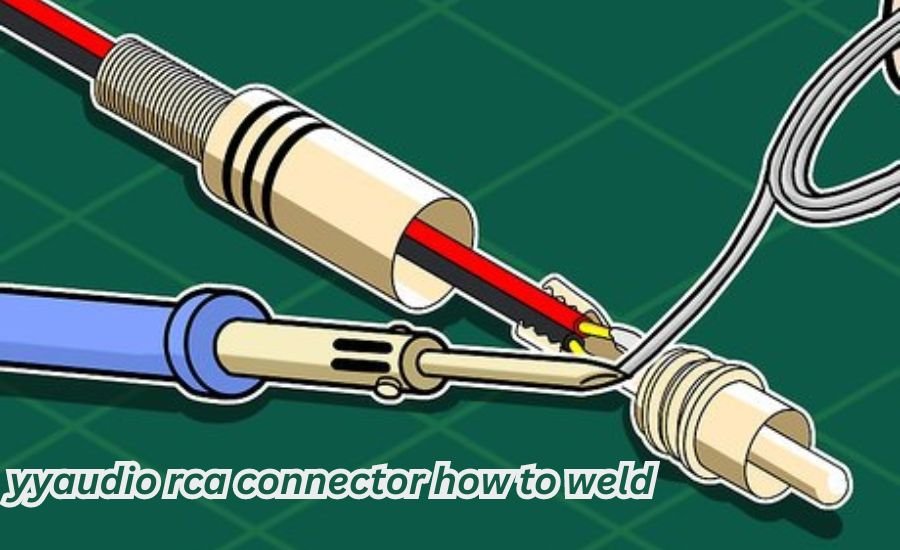

Step-by-Step Process on YYAudio Rca Connector how to weld

Welding YYAudio RCA connectors can be simple when you follow a step-by-step process. Start by gathering all your materials and tools. Once you are ready, the first step is to prepare your cables. Use wire strippers to carefully remove the outer layer of insulation, exposing the inner wires that you will weld.

After preparing the wires, it’s time to tin them. Tinning means melting a little solder onto the exposed wires to make them easier to connect to the RCA connectors. This step is essential in ensuring a strong connection, especially when you focus on YYAudio Rca Connector and how to weld properly.

Here’s a more detailed step-by-step process for welding YYAudio RCA connectors based on your provided paragraph:

Step 1: Gather Materials and Tools

- Materials Needed:

- YYAudio RCA connectors

- Cables with inner wires

- Solder

- Tools Needed:

- Wire strippers

- Soldering iron

- Soldering stand (optional)

- Heat shrink tubing (optional)

- Multimeter (for testing connections)

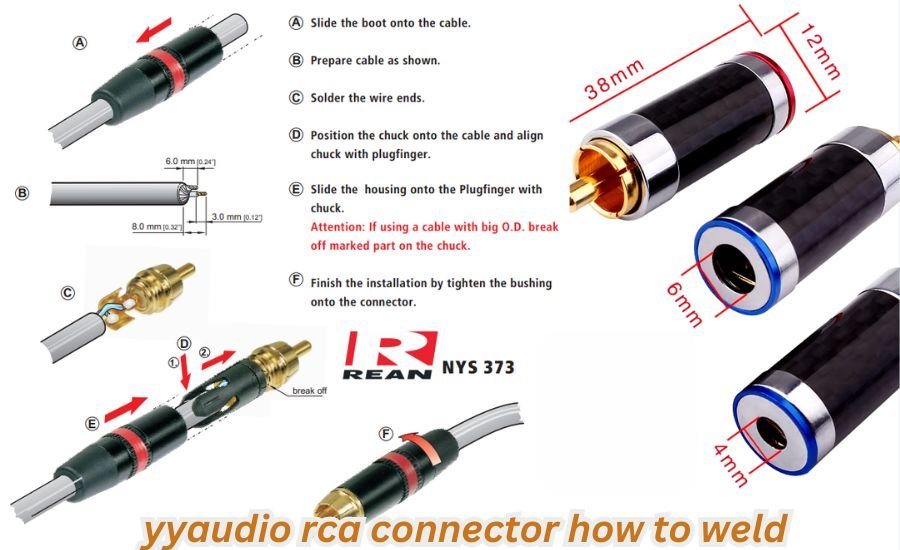

Step 2: Prepare Your Cables

- Remove Insulation:

- Use wire strippers to carefully strip the outer insulation of your cables, exposing the inner wires.

- Make sure to strip enough length to work with, usually around 1/2 inch (1.27 cm).

Step 3: Tin the Wires

- Apply Solder:

- Turn on the soldering iron and allow it to heat up.

- Melt a small amount of solder onto the exposed ends of the wires. This process is called tinning and helps to create a stronger bond with the RCA connectors.

- Make sure the solder flows evenly over the wires.

Step 4: Identify RCA Connector Parts

- Recognize Components:

- Take your YYAudio RCA connector and identify the two main parts: the pin (center) and the outer ring (ground).

- Ensure you have a clear understanding of which wire connects to which part.

Step 5: Solder the Wires to the RCA Connector

- Make the Connection:

- Carefully solder the center (positive) wire to the pin of the RCA connector.

- Solder the outer (negative) wire to the outer ring of the connector.

- Use a steady hand and avoid touching other parts of the connector to prevent short circuits.

Step 6: Check Connections

- Inspect the Solder Joints:

- Once the soldering is complete, visually inspect the connections to ensure they are secure and free from any solder bridges or shorts.

- Optionally, you can use a multimeter to test the continuity of your connections.

Step 7: Insulate the Connections (Optional)

- Use Heat Shrink Tubing:

- If you have used heat shrink tubing, slide it over the soldered area and use a heat source (like a heat gun) to shrink it down, providing insulation and protection.

Step 8: Final Inspection

- Verify the Assembly:

- Ensure all connections are solid and secure.

- Make sure the RCA connector fits snugly without any loose parts.

Step 9: Test the Connection

- Check Audio Performance:

- Connect your assembled YYAudio RCA connectors to your audio equipment.

- Test the sound quality to ensure proper function and connectivity.

Common Mistakes to Avoid When Welding RCA Connectors

When learning YYAudio Rca Connector how to weld, it’s important to be aware of common mistakes. One frequent error is overheating the wires or connectors. This can damage both components and ruin the connections you are trying to create. Always use the soldering iron at the right temperature and keep it moving to avoid overheating during the process of the YYAudio Rca Connector how to weld.

Another mistake is using too much solder. While it might seem helpful to add more, too much solder can create blobs that lead to short circuits. Instead, apply just enough solder to make a strong and clean connection without excess, especially when practicing your skills in YYAudio Rca Connector and how to weld.

Additionally, remember to check the polarity before soldering. Ensure that the inner wire goes to the pin and the outer wire connects to the ring. If you reverse these, your audio might not work properly. By avoiding these common mistakes, you can enhance your skills in YYAudio Rca Connector and how to weld effectively.

Troubleshooting Common Issues with YYAudio RCA Connections

After welding YYAudio RCA connectors, you may encounter some common issues. One common problem is sound distortion, which can appear as crackling or buzzing sounds. If you notice this, check your connections. Loose or poorly soldered joints can cause these issues. If necessary, re-solder the connections to resolve the problem when learning YYAudio Rca Connector how to weld.

Another issue could be a complete lack of sound. This might be due to a broken wire or a faulty connector. To troubleshoot, inspect the entire cable for signs of damage. If you find cuts or frayed wires, remove the damaged section with wire strippers and re-solder it securely. Being able to fix these issues shows how important understanding YYAudio Rca Connector and how to weld really is.

Finally, interference can affect audio quality. If you hear unwanted noise, ensure your cables are not running near power cords or other electronic devices. Keeping your audio cables organized and separated from potential sources of interference can help maintain a clear sound. By understanding how to troubleshoot these issues, you can keep your YYAudio RCA connections working smoothly.

Upgrading Your Audio System with Quality RCA Connections

Upgrading your audio system often involves using high-quality YYAudio RCA connectors. These connectors can significantly improve sound clarity and reliability. When you switch to better connectors, you can expect clearer highs and deeper lows, enhancing your audio experience. Knowing how to weld the YYAudio Rca Connector can help you achieve these improvements.

To upgrade effectively, start by evaluating your current cables and connectors. If they are worn out or damaged, replacing them with new YYAudio RCA connectors can make a big difference in sound quality. Additionally, using well-shielded cables can minimize interference, allowing for optimal audio performance when you learn YYAudio Rca Connector how to weld correctly.

Another way to upgrade is to ensure all your connections are soldered correctly. Well-welded connectors provide strong links between your devices. This step is crucial, as weak connections can lead to sound loss or distortion. Investing time in upgrading your connections will lead to a more enjoyable audio experience, especially when you know YYAudio Rca Connector how to weld effectively.

The Importance of Soldering in Audio Applications

Why Soldering is Essential

Soldering is vital in audio applications, especially when working with YYAudio RCA connectors. It creates strong and reliable connections that ensure high-quality sound transmission. Without proper soldering, audio signals can weaken, leading to distortion or loss of sound. Understanding how to solder YYAudio RCA connectors properly is essential for optimal audio performance.

The Soldering Process

When you solder, you melt a small amount of solder to join the wires and connectors. This process helps establish a solid bond that can withstand wear and tear over time. A well-soldered connection lasts much longer than a simple plug-in connection, making it a preferred choice for serious audio enthusiasts who want to learn how to solder YYAudio RCA connectors.

Benefits of Good Soldering Techniques

Good soldering techniques can help prevent interference. By creating tight and clean connections, you reduce the chances of noise affecting your audio. As a result, mastering soldering is essential for anyone looking to build or repair audio equipment. Understanding its importance will help you achieve the best audio results, especially when learning how to solder YYAudio RCA connectors.

You May Also Like: U231748506

Comparing YYAudio RCA Connectors to Other Audio Connectors

When choosing audio connectors, comparing YYAudio RCA connectors with other types is beneficial. RCA connectors are easy to use and reliable, making them ideal for home setups with speakers and amplifiers. In contrast, XLR connectors, used in professional audio setups, reduce noise but are more complex. The 3.5mm audio jack is convenient for portable devices but may not match the quality of RCA connectors in larger systems. Ultimately, YYAudio RCA connectors provide a straightforward and versatile connection.

| Connector Type | Use Case | Advantages | Disadvantages |

| YYAudio RCA Connectors | Home audio setups | Easy to use, reliable performance | Limited noise reduction |

| XLR Connectors | Professional audio environments | Balanced design reduces noise | More complex to use, requires specific equipment |

| 3.5mm Audio Jack | Headphones and portable devices | Convenient and widely compatible | May not provide high-quality sound for larger systems |

Tips for Maintaining Your Audio Equipment After Welding

After successfully welding YYAudio RCA connectors, it’s important to maintain your audio equipment for long-lasting performance. Start by regularly checking your connections for any signs of wear. Look for frayed wires or loose solder joints. Addressing these issues early can prevent more significant problems in the future, ensuring that your YYAudio RCA connectors continue to work well.

Here are some additional tips for maintaining your audio equipment after welding:

Regular Inspections

- Check for Corrosion: Along with looking for frayed wires and loose solder joints, inspect your connectors and cables for any signs of corrosion. Use a soft cloth to clean connectors and ensure a good electrical connection.

- Test Connections: Periodically test your audio equipment by plugging in and unplugging connectors to ensure they fit snugly and function properly. This helps identify any issues with the connections.

Cable Management

- Use Proper Cable Management Tools: Invest in cable organizers, such as sleeves or wraps, to keep multiple cables together. This prevents tangling and reduces the risk of wear and tear.

- Avoid Overextending Cables: Be mindful of how far you stretch your audio cables. Overextending can lead to stress on connectors and wires, potentially causing damage.

Environment Considerations

- Avoid Direct Sunlight: Store your audio equipment away from direct sunlight to prevent overheating and fading of materials. Use protective cases or covers to shield them from environmental elements.

- Control Humidity Levels: Consider using a dehumidifier in your storage area if you live in a humid climate. High humidity can cause damage to electronic components over time.

Handling Precautions

- Be Gentle with Connectors: When connecting or disconnecting your YYAudio RCA connectors, do so gently to avoid putting undue stress on the soldered joints.

- Limit Movement: Try to minimize moving your audio equipment frequently. Constant relocation can lead to wear on connectors and cables.

Routine Cleaning

- Dust and Dirt Removal: Regularly clean your audio equipment with a soft, dry cloth to remove dust and dirt. Avoid using harsh chemicals that could damage the surfaces or connections.

- Maintain a Clean Workspace: When working with audio equipment, ensure your workspace is clean and free from debris that could accidentally damage components during handling.

By implementing these additional tips alongside the original maintenance suggestions, you can help ensure your audio equipment remains in excellent condition and continues to deliver high-quality sound for years to come.

Expanding Your Skills: Other Welding Techniques for Audio Connectors

Using Heat-Shrink Tubing

Once you’ve mastered YYAudio Rca Connector and how to weld, consider exploring other welding techniques for audio connectors. One popular method is using heat-shrink tubing. This technique provides additional protection for soldered connections. By learning this skill, you can ensure even greater durability and reliability for your audio setups.

Understanding Crimp Connectors

Another technique is using crimp connectors, which involve mechanically joining wires instead of using solder. While this method is less common for RCA connectors, it’s valuable to know for other types of audio connections. Understanding how to use various welding methods can help you choose the best option for your audio projects.

Practicing on Different Types of Connectors

Additionally, consider practicing your welding skills on different types of connectors. Each connector type may require slightly different techniques, so getting familiar with various methods will expand your capabilities. As you grow your expertise, you will be better equipped to tackle a wide range of audio projects, including those that require knowing YYAudio Rca Connector how to weld effectively.

Safety Tips for Welding YYAudio RCA Connectors

- Wear Protective Gear: Always wear safety glasses to protect your eyes from solder splashes and flying debris. Use gloves to protect your hands from heat and sharp edges.

- Work in a Well-Ventilated Area: Ensure your workspace is well-ventilated to avoid inhaling harmful fumes from soldering. If possible, work outdoors or near a fan.

- Use a Soldering Iron Stand: Always place your hot soldering iron in a designated stand when not in use. This prevents accidental burns and fires.

- Avoid Flammable Materials: Keep flammable materials away from your work area. Soldering can generate heat, which may ignite nearby items.

- Handle Tools Carefully: Be mindful when handling tools. Avoid touching the hot tip of the soldering iron, and ensure wires are not under tension.

- Keep a Fire Extinguisher Nearby: Always have a fire extinguisher nearby in case of emergencies. Make sure you know how to use it.

- Disconnect Power Sources: Before starting any work on audio equipment, unplug devices to avoid electrical shocks.

- Check Equipment for Damage: Regularly inspect your soldering iron, wires, and connectors for any damage. Do not use damaged equipment.

- Stay Focused: Avoid distractions while welding. Concentration is key to ensuring safety and producing good-quality connections.

- Read Manufacturer Instructions: Familiarize yourself with the specific instructions for the materials and tools you are using to ensure safe handling.

By following these safety tips, you can create a safer working environment while welding YYAudio RCA connectors.

Conclusion

In conclusion, YYAudio RCA connectors are a great choice for anyone working on audio projects. Learning YYAudio Rca Connector and how to weld makes it easier to connect speakers and amplifiers. When you know YYAudio Rca Connector how to weld properly, you can make your audio setup even better. This leads to better sound quality and fewer issues over time!

While there are other connectors like XLR and 3.5mm jacks, YYAudio RCA connectors stand out for their simplicity and reliability. Understanding YYAudio Rca Connector how to weld can help you choose the right connector for your needs. Each type has its strengths, but for everyday use, knowing YYAudio Rca Connector how to weld can make your audio projects successful.

Read Next: Ittadi Shop

FAQs

Q: What are YYAudio RCA connectors used for?

A: YYAudio RCA connectors are used to connect audio devices like speakers, amplifiers, and audio players, providing reliable audio signals.

Q: How do I weld YYAudio RCA connectors?

A: To weld YYAudio RCA connectors, strip the wire ends, heat the soldering iron, apply solder to the wires, and connect them to the RCA connector pins.

Q: Why should I learn YYAudio Rca Connector how to weld?

A: Learning to weld YYAudio RCA connectors allows you to create custom audio cables, ensuring better quality connections and improved sound.

Q: Can I use YYAudio RCA connectors for professional audio setups?

A: While YYAudio RCA connectors are excellent for home use, XLR connectors are preferred for professional setups due to their balanced design.

Q: How can I maintain my YYAudio RCA connectors?

A: Regularly check for wear, keep cables organized, and store equipment in a cool, dry place to maintain YYAudio RCA connectors effectively.

Q: What should I do if my YYAudio RCA connectors are not working?

A: If your YYAudio RCA connectors are not working, check for loose connections, inspect for damaged cables, and ensure that all devices are powered on.

Q: Are YYAudio RCA connectors compatible with all audio devices?

A: YYAudio RCA connectors are compatible with most audio devices that have RCA input/output options, but not with devices that require different connector types.